Bin System In Warehouse

Bin system in warehouse. Watch the video below to see how the WiSys Warehouse Management System uses bins and lots to make traceability easy. If you have anything in your warehouse that requires additional security wire partitions are a great option as they can be modified in shape and expanded or reduced as needed. The Bin Warehouse wall storage system has a simple design that is user-friendly and easy to assemble.

The 2-bin Kanban system is a lean manufacturing supply chain management method aimed at reducing inventory and optimizing processes. As you can see this 100 garage storage unit eliminates the clutter and keeps everything neat. You will need a meaningful bin numbering system for each warehouse.

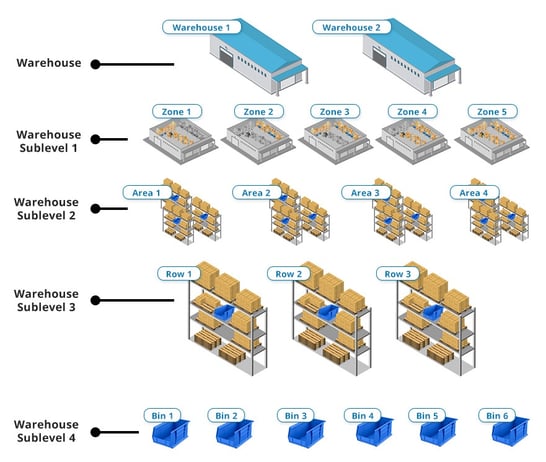

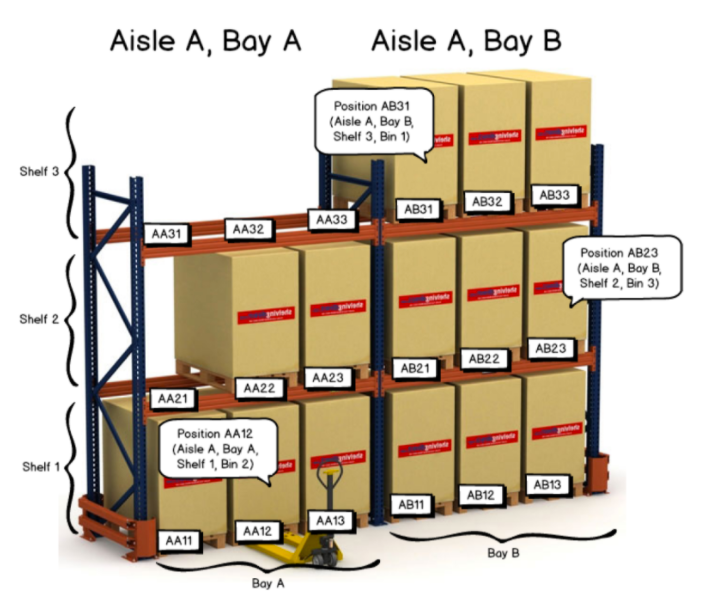

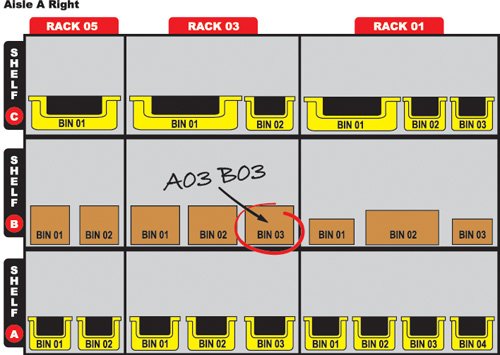

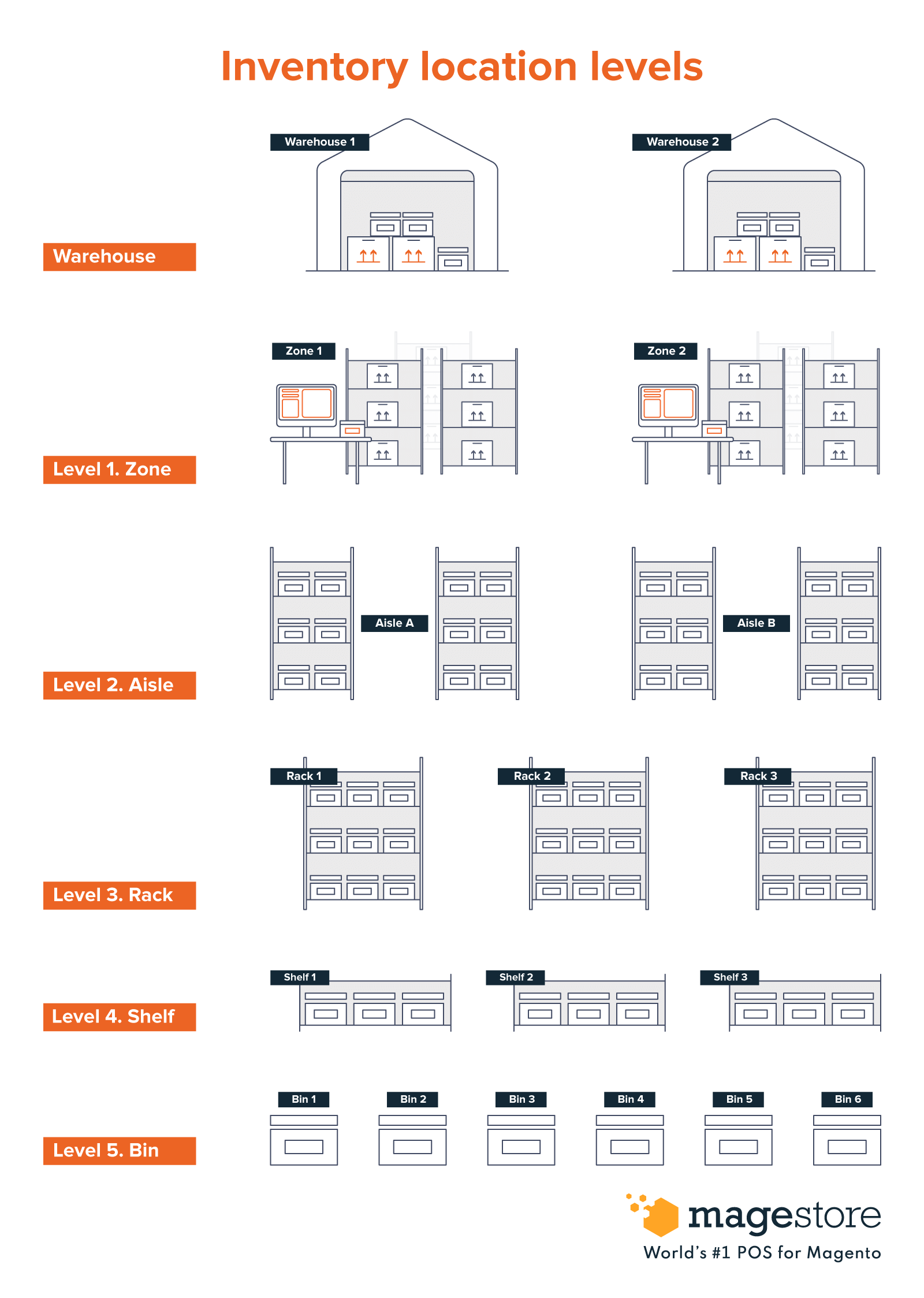

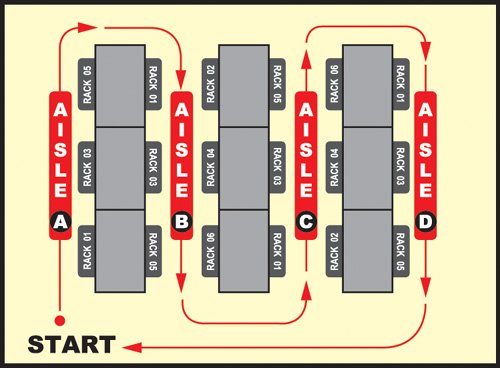

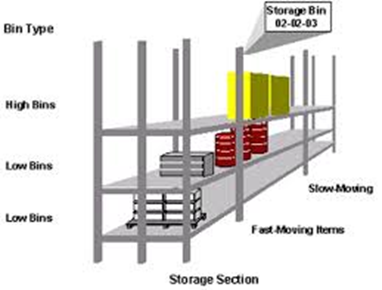

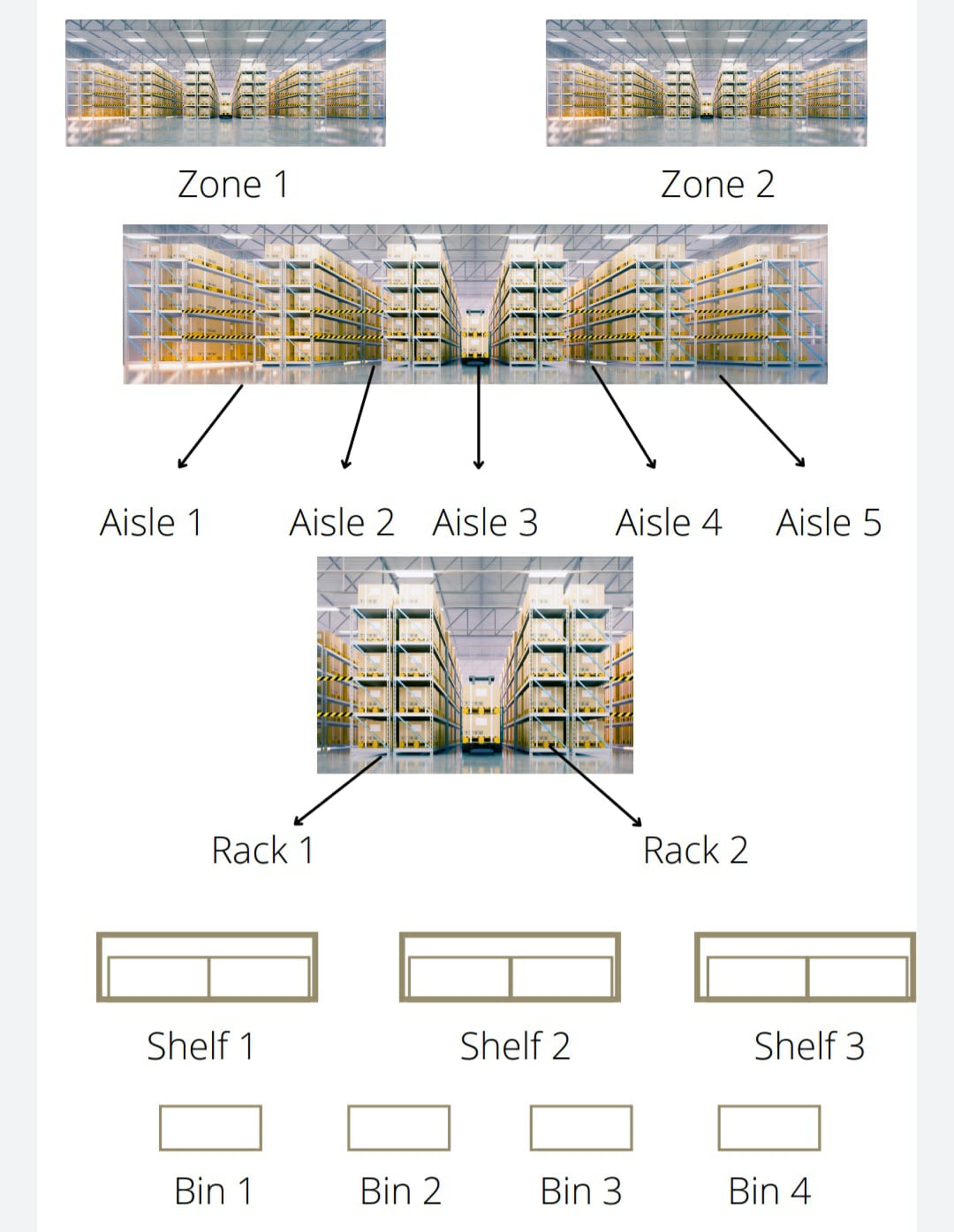

To create a bin from the location card. Proper labeling of bins and racks will help minimize errors in product picking. Most warehouse operations use three dimensions to indicate the location of items.

Maximizing scanning and decoding speed. Bin locations simplify the inventory management processes ensuring merchants always know where to store and find their products. Aisle identification vertical section and level number.

Once you secure the frame to wall the storage unit is surprisingly. Employees in industrial warehouses mechanics garages and other technical fields rely on the superior organization and secure storage of bin shelves. Bin location is the smallest unit of space inside a warehouse where merchants store their goods.

Warehouse Management Solutions for SAP Business One and Macola Software WiSys Agility solutions have been designed to achieve efficient Warehouse Management Supply Chain Management and Inventory Management for SAP Business One. Essentially it consists of a heavy-duty PVC frame that holds 12 giant storage bins. Using bins makes it possible to have one item that is stored in many different places in the inventory and make the system control that and manage the quantities and all the different bins and its very cool because its easy to find the item and you get a very high accuracy on the inventory meaning everything is correct if you do the postings.

This video explains how to make proper bin location of your storage area or warehouse under the T cloud ERPDownload bin location labels for print from here. However if you can store multiple pallets on a given rack position you can add a fourth dimension.

Using bins makes it possible to have one item that is stored in many different places in the inventory and make the system control that and manage the quantities and all the different bins and its very cool because its easy to find the item and you get a very high accuracy on the inventory meaning everything is correct if you do the postings.

Bin locations simplify the inventory management processes ensuring merchants always know where to store and find their products. You will need a meaningful bin numbering system for each warehouse. This accessible warehouse inventory template allows users to track and maintain inventory bin locations within a warehouse. You can also use a function in the Bin Creation Worksheet window to create bins automatically. This adds to the total location id Warehouse AA bin location AABBCC because this is part of the stock-code-warehouse locations but the facts are it is only 6 digits. The most effective way to create the bins of your warehouse is to generate groups of similar bins in the bin creation worksheet but you can also create your bins individually from the location card. Bin locations simplify the inventory management processes ensuring merchants always know where to store and find their products. Some storage bins are made out of special material such as polypropylene which is resistant to extreme cold and can withstand temperatures up to 250 degrees Fahrenheit. To create a bin from the location card.

Warehouse Management Solutions for SAP Business One and Macola Software WiSys Agility solutions have been designed to achieve efficient Warehouse Management Supply Chain Management and Inventory Management for SAP Business One. Using bins makes it possible to have one item that is stored in many different places in the inventory and make the system control that and manage the quantities and all the different bins and its very cool because its easy to find the item and you get a very high accuracy on the inventory meaning everything is correct if you do the postings. This adds to the total location id Warehouse AA bin location AABBCC because this is part of the stock-code-warehouse locations but the facts are it is only 6 digits. If you set up the warehouse that way without a mechanism to find the stuff youre going to be in a lot of trouble. Most warehouse operations use three dimensions to indicate the location of items. The Bin Warehouse wall storage system has a simple design that is user-friendly and easy to assemble. This allows staff new to your warehouse pick things up quickly.

Post a Comment for "Bin System In Warehouse"